Making of

© LDA, Illustration: Karol Schauer.

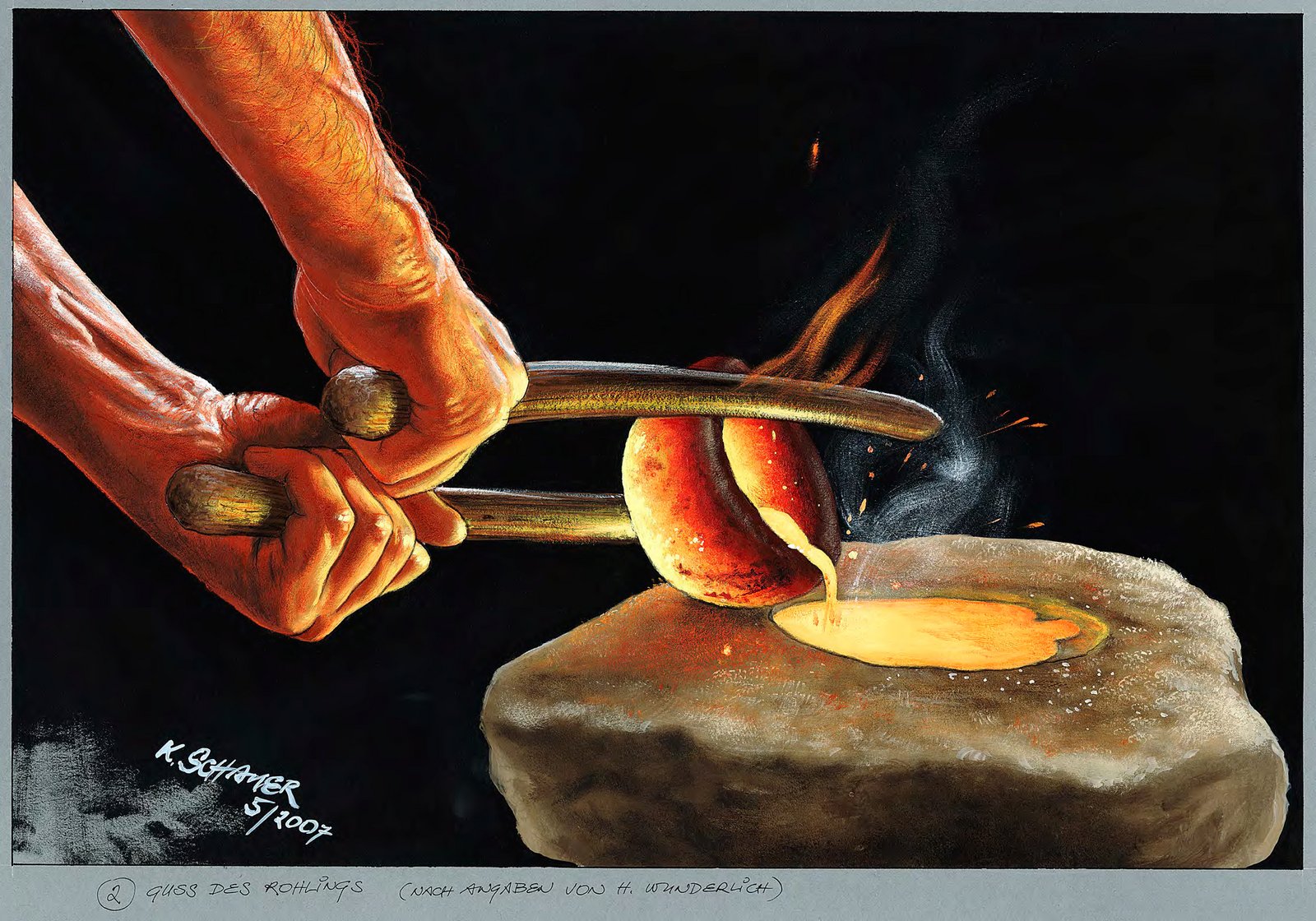

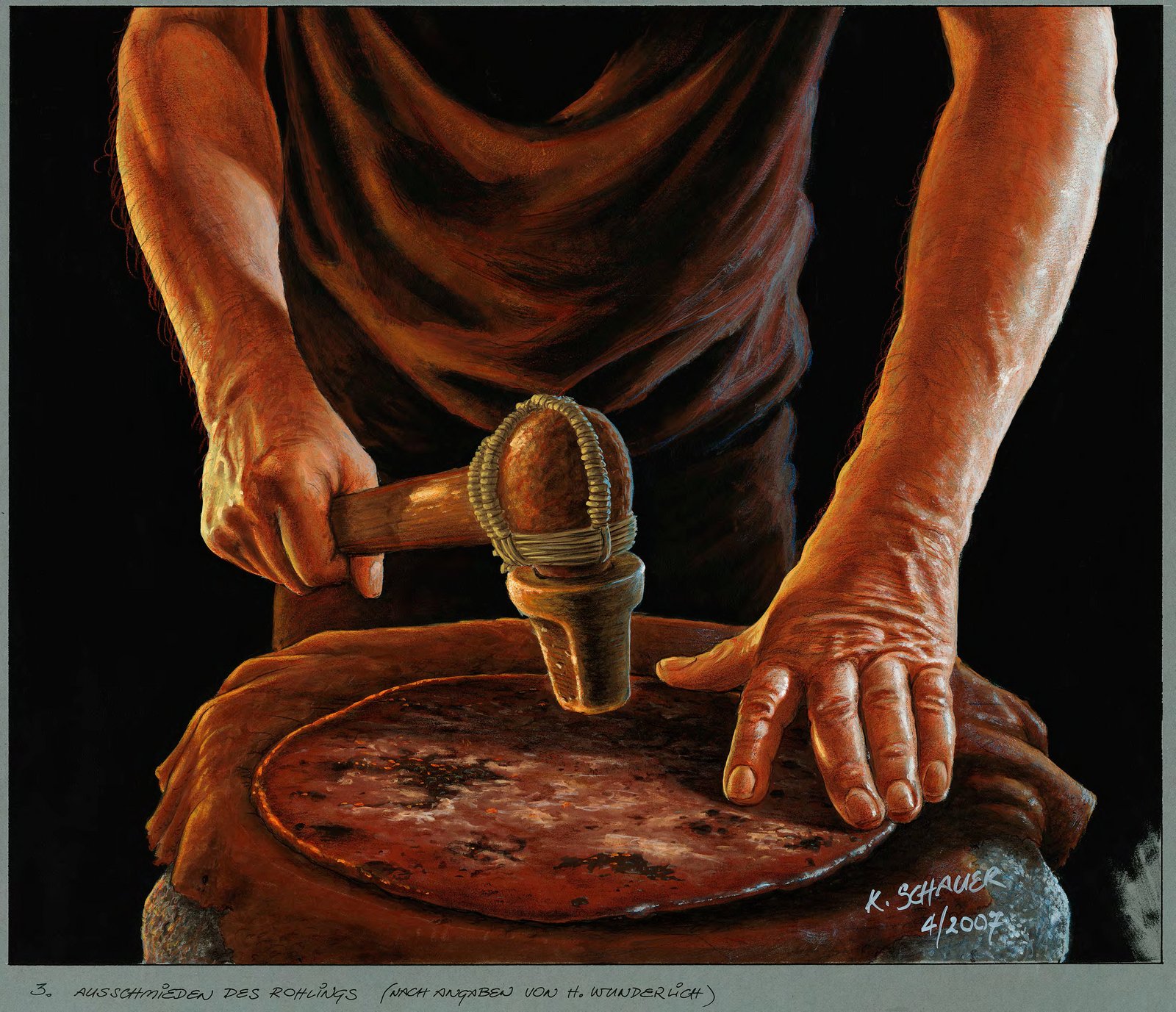

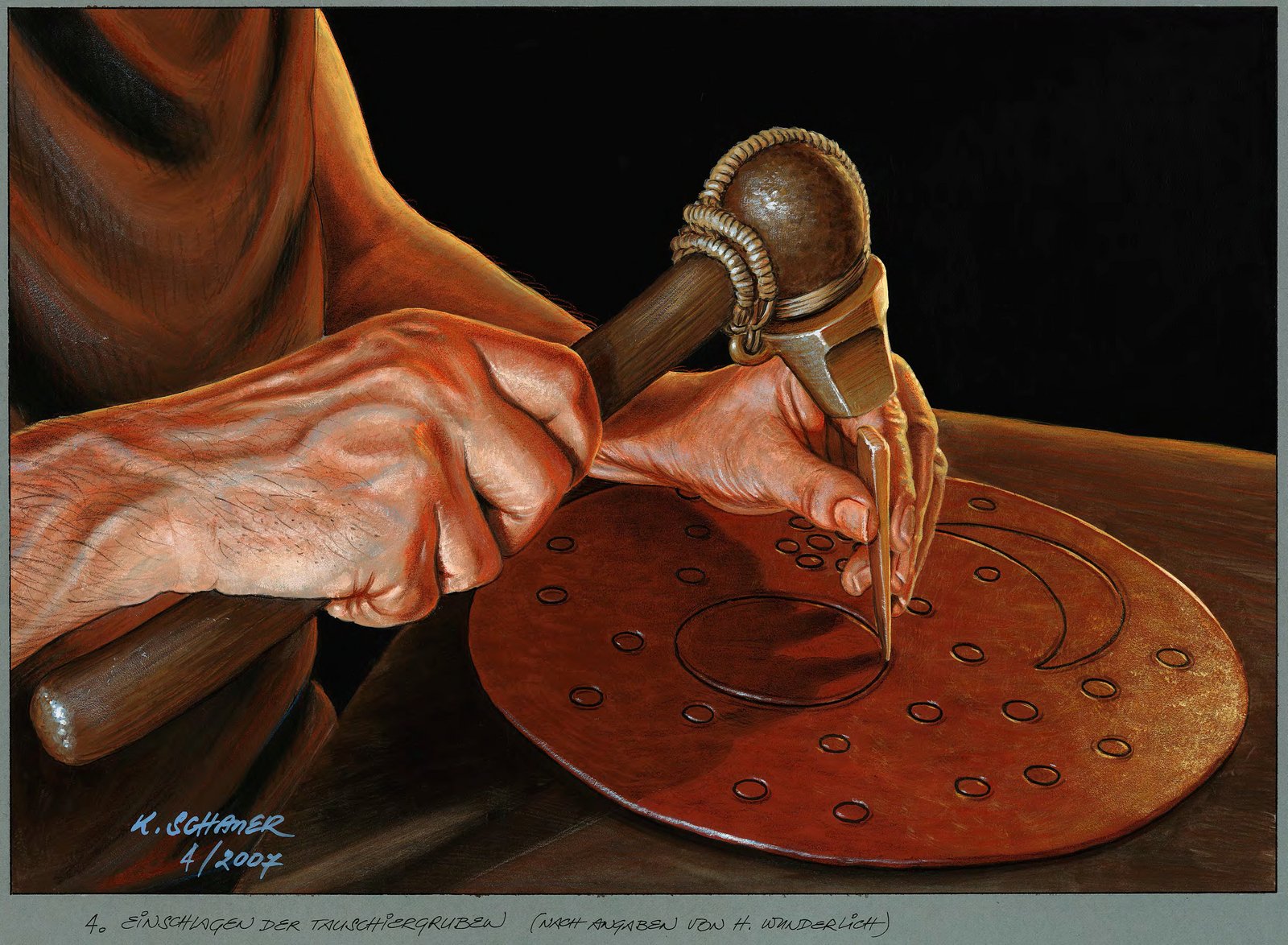

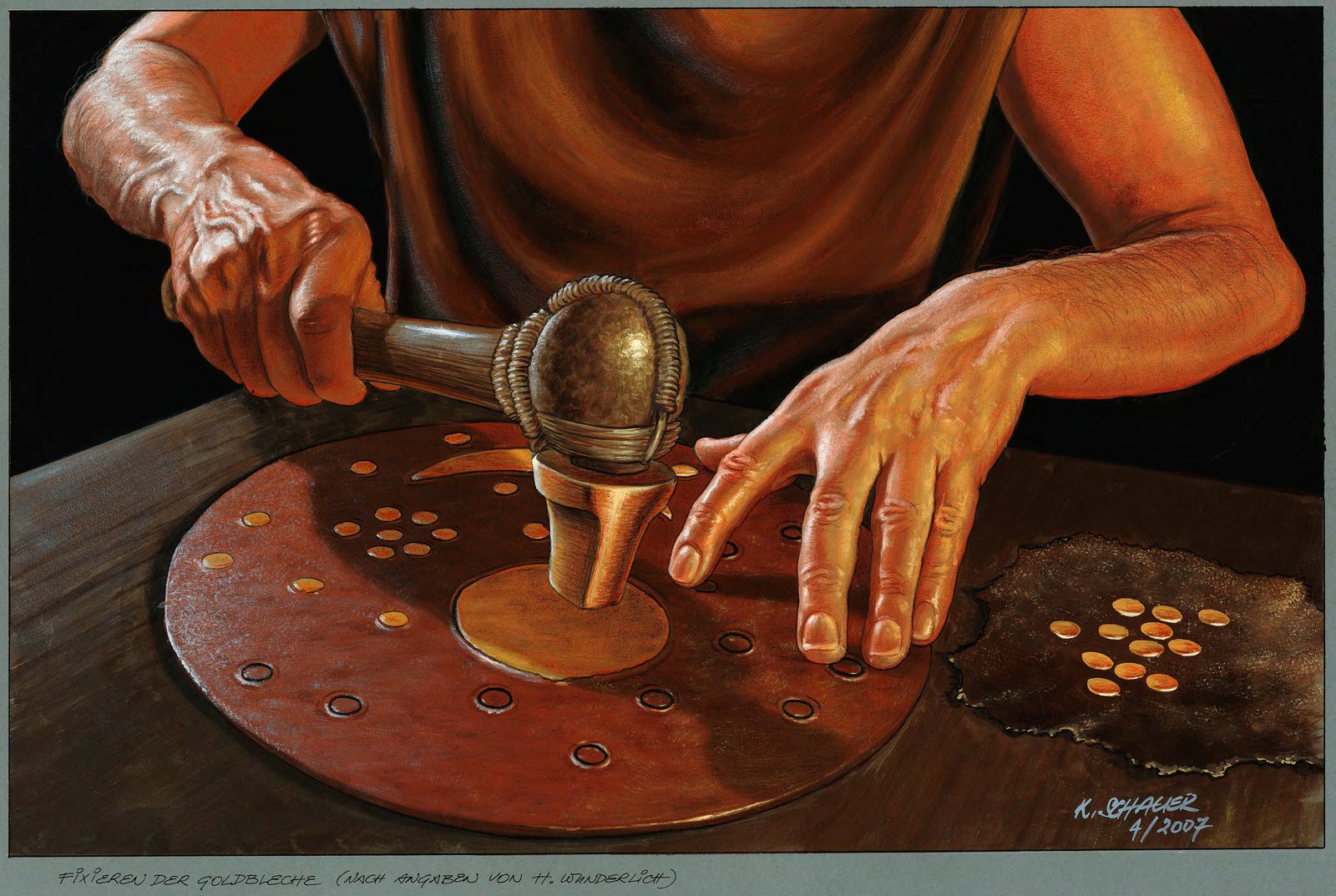

After the casting of the blank, it was driven out with a hammer-like tool. This means that the blank was forged into a circular, flat shape. To avoid cracks in the bronze, it was reheated several times in between.

In contrast to the accompanying finds – which were cast in a mould – the Sky Disc was forged from a cooled bronze casting cake.

© LDA, Illustration: Karol Schauer.

© LDA, Illustration: Christian-Heinrich Wunderlich.

© LDA, Illustration: Karol Schauer.

© LDA, Illustration: Christian-Heinrich Wunderlich.

© LDA, Illustration: Klaus Pockrandt.

Today’s green colour is the result of the corrosion process to which the Sky Disc was exposed for several millennia. This led to the green malachite layer that covers the disc today.

We assume that the original Sky Disc was dark. Against a bronze-coloured background, the gold appliqués would barely have stood out. A black patina could be created by slowly heating and carefully polishing the disc.